Featured Story:

Kreisler Industrial

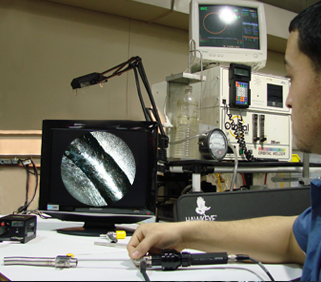

Kreisler Industrial employs a “very aggressive borescope inspection” in order to detect defects earlier in the manufacturing process of aviation parts. Kreisler uses Gradient Lens Corporation’s Hawkeye Precision Borescopes to inspect weld joints to ensure the quality of the weld is acceptable and that the part is flight worthy. All of Kreisler’s welders and weld operators have been trained in visual inspection requirements and perform borescopic inspections... learn more